2025’s Cutting-Edge Innovations in Wrapping Machines: A Global Buyer’s Essential Checklist

In the rapidly evolving landscape of packaging technology, wrapping machines stand at the forefront of innovation, significantly enhancing efficiency and productivity across various sectors. According to a recent report by Grand View Research, the global packaging machinery market is projected to reach USD 60.8 billion by 2025, with wrapping machines playing a crucial role in driving this growth due to their versatility and advanced capabilities. As manufacturers seek to streamline operations and meet growing consumer demands for sustainability and reduced waste, the integration of cutting-edge technologies such as automation, smart sensors, and eco-friendly materials is becoming increasingly essential. This comprehensive checklist for global buyers not only highlights the key trends and innovations in wrapping machines but also assists in making informed decisions to stay competitive in the packaging industry.

Key Features to Look for in 2025 Wrapping Machines: Efficiency and Versatility

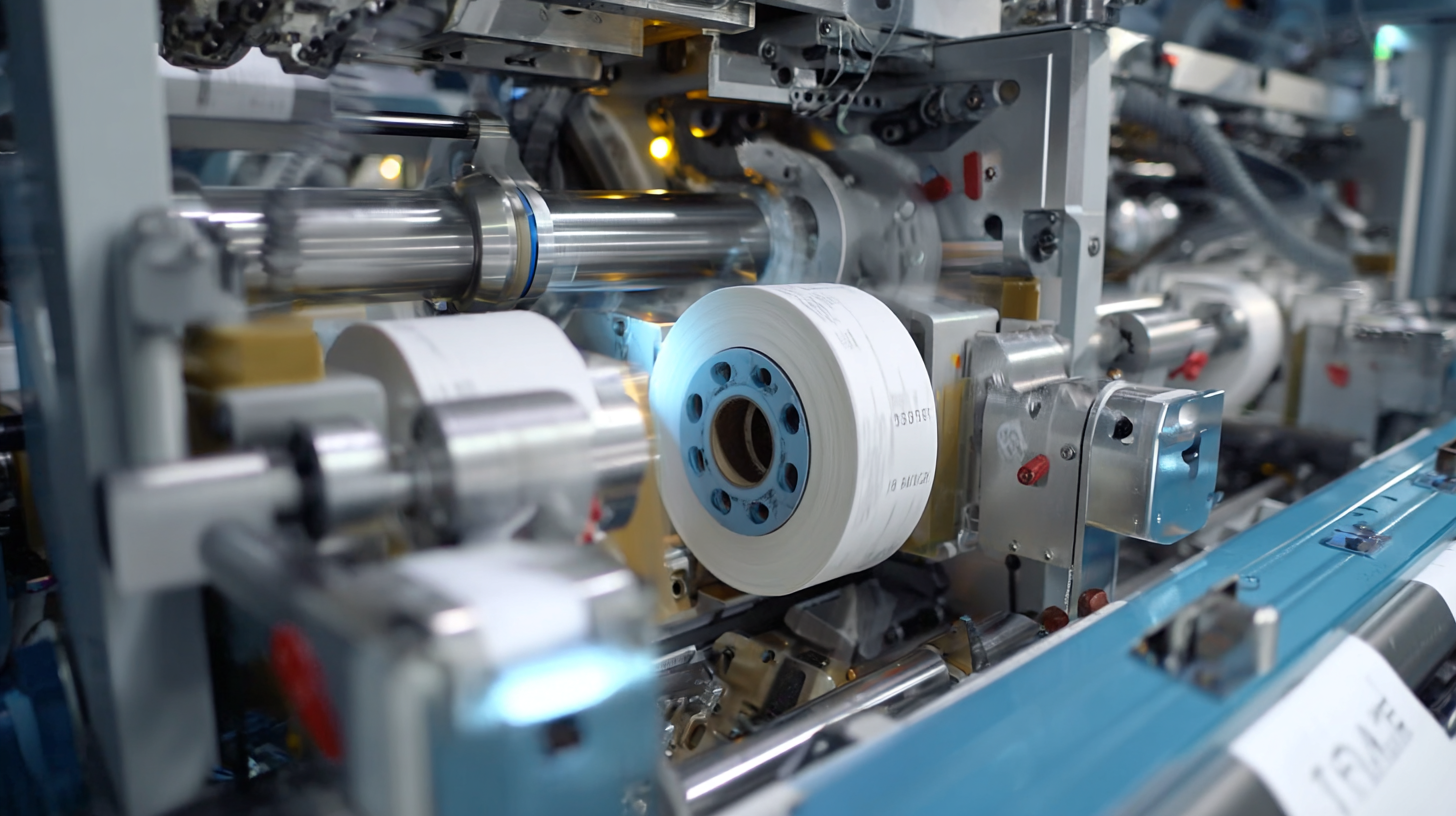

As we dive into 2025, the wrapping machine industry is set to embrace remarkable innovations that enhance both efficiency and versatility. When searching for the perfect wrapping machine, buyers should prioritize features that optimize productivity while maintaining flexibility in packaging options. Look for machines that offer adjustable settings, allowing for a range of product sizes and types. This adaptability ensures that your operational needs are met without the need for constant equipment changes.

Tip: Always evaluate the user interface of the wrapping machine. A machine equipped with an intuitive control panel can significantly reduce training time and minimize operational errors. Additionally, check if the machine supports integration with existing manufacturing systems, as this can boost overall efficiency and streamline workflows.

Another critical aspect to consider is the machine's speed and throughput capabilities. In a fast-paced market, the ability to wrap products quickly while ensuring quality is paramount. High-speed wrapping machines that employ advanced technologies can handle increased production demands without compromising on standards.

Tip: Conduct thorough research on the machine's maintenance requirements. Machines that are easy to maintain not only save time and labor costs but also prolong the lifespan of your equipment, ensuring uninterrupted production processes. Consider warranty terms and the availability of technical support, which play essential roles in long-term operational success.

The Role of Automation in Modern Wrapping Solutions for Global Buyers

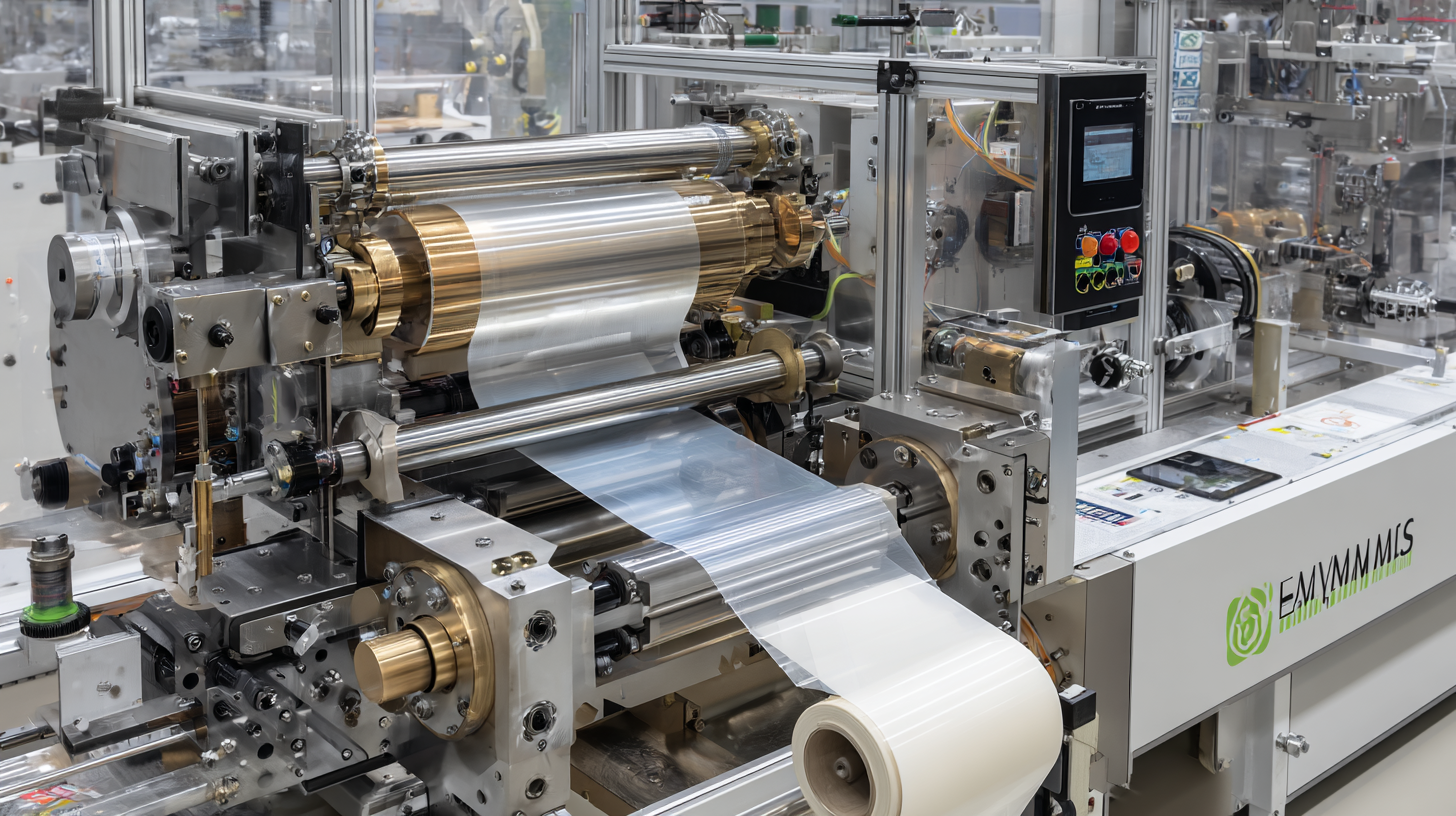

In the evolving landscape of wrapping machines, automation plays a pivotal role in enhancing efficiency and precision. As global buyers prepare for the Asian Industrial Online Exhibition 2025, they will witness firsthand how state-of-the-art automated packaging solutions are reshaping the industry. These innovations not only streamline the wrapping process but also minimize human intervention, reducing labor costs and increasing throughput. Automated machines can seamlessly fill, cap, and seal products, ensuring consistent quality and reducing the chances of errors in production lines.

Moreover, the end-of-line packaging sector is seeing remarkable advancements, promising significant growth in the upcoming years. As businesses prioritize efficiency, integrating automated systems at the end of the packaging line is becoming crucial. These technologies allow for rapid adaptability to changing production demands while maintaining high standards. For global buyers attending the exhibition, understanding the latest trends in automation will be essential for making informed decisions and optimizing their packaging strategies. Embracing automation in wrapping solutions positions businesses at the forefront of the competitive packaging market.

Sustainability Trends in Wrapping Machine Innovations: Eco-Friendly Materials and Practices

As we approach 2025, the emphasis on sustainability trends in wrapping machine innovations has become increasingly vital. With a significant rise in eco-conscious consumers, businesses are recognizing the importance of adopting eco-friendly materials and practices in their packaging solutions. The trend towards sustainable packaging continues to gain momentum as customers express a willingness to pay a premium—up to 9.7%—for products that feature high-quality, environmentally responsible packaging. This shift reflects an evolving consumer mindset that prioritizes environmental impact when making purchasing decisions.

The innovations in wrapping machines are playing a crucial role in this transition towards sustainability. Manufacturers are increasingly focusing on developing packaging materials that are not only recyclable but also biodegradable, ensuring that the end-of-life implications of their products align with circular economy principles. As concerns over plastic pollution intensify, the demand for eco-packaging solutions is set to accelerate in 2025, leading to innovations that facilitate easy recycling and minimize the use of harmful materials. The adoption of these practices is not merely a trend; it represents a fundamental change in how businesses operate and engage with their customers to create a more sustainable future.

Cutting-Edge Technologies Enhancing User Experience and Operational Efficiency

The evolution of wrapping machines is rapidly shaping the packaging industry, with 2025 set to showcase extraordinary innovations that enhance both user experience and operational efficiency. Cutting-edge technologies are central to this transformation, offering features such as intuitive interfaces, machine learning algorithms, and advanced robotics that streamline production lines. These advancements foster a productive environment, allowing operators to easily navigate complex tasks while reducing the potential for errors.

Tip: When evaluating wrapping machines, prioritize those that feature user-friendly controls. An intuitive interface not only boosts productivity but also minimizes training time for operators, facilitating smoother transitions during onboarding.

Moreover, machine connectivity is a game-changer, enabling real-time data analysis and remote monitoring. This connectivity allows businesses to make informed decisions based on performance metrics, leading to timely maintenance and reduced downtime. As smart technology continues to integrate into wrapping processes, companies can expect enhanced efficiency and sustainability.

Tip: Invest in wrapping machines that support IoT capabilities. This will not only optimize your operational efficiency but also provide insights into the packaging process, allowing for continuous improvement and cost savings in the long run.

2025’s Cutting-Edge Innovations in Wrapping Machines: A Global Buyer’s Essential Checklist

| Feature | Description | Benefits | Expected Impact |

|---|---|---|---|

| Smart Sensors | Utilizes sensors for real-time monitoring of packaging materials. | Reduces material waste, enhances quality control. | Improved sustainability and cost-effectiveness. |

| Automated User Interface | Touchscreen controls for easy operation and programming. | Simplifies training for operators, reduces errors. | Increased operational efficiency. |

| Energy Efficiency | Advanced motors and drives that consume less power. | Lowers operational costs and carbon footprint. | Environmental benefits and savings. |

| Modular Design | Allows customization and easy upgrades of machine components. | Flexibility to adapt to changing production needs. | Reduced downtime and improved lifespan. |

| IoT Connectivity | Integration with IoT platforms for remote monitoring. | Enhances maintenance capabilities and reduces downtime. | Faster response to operational issues. |

Comparing Different Types of Wrapping Machines: Which is Right for Your Business?

When selecting the right wrapping machine for your business, it's essential to evaluate the various types available, each designed to meet specific operational needs. For instance, stretch film wrap machines are ideal for wrapping palletized goods, providing excellent load stability and protection against dust and moisture. These machines are perfect for warehouses looking to enhance their efficiency while ensuring that products are securely packed.

Alternatively, shrink wrapping machines offer a different approach by using heat to shrink film tightly around products. This method not only offers superior protection from tampering and environmental factors but also provides an aesthetically pleasing presentation, making it suitable for retail and food packaging. Each machine type comes with its own set of features and capabilities, so understanding your product specifications and packaging goals is critical in making the best choice.

Lastly, consider the automation level of the wrapping machines. Fully automated machines tend to offer higher speed and consistency, making them ideal for high-volume production lines. However, semi-automated machines may be more suited for smaller operations that require flexibility without the need for large upfront investments. Assess your production needs and budget to find the wrapping solution that aligns with your business objectives.