How to Choose the Right Sealing Machine for Your Business Needs

In today's competitive market, selecting the right sealing machine is crucial for enhancing productivity and ensuring product integrity. According to a recent report by Grand View Research, the global sealing machine market is projected to reach $5.86 billion by 2025, indicating significant growth driven by the rising demand for packaged goods across various industries. Businesses must adapt to evolving consumer preferences, which increasingly favor sustainable and reliable packaging solutions. Moreover, with the integration of smart technology into sealing machines, companies can optimize their operations, reduce waste, and improve consistency in product sealing. Understanding the specific requirements of your business, alongside the various types of sealing machines available—such as heat sealers, vacuum sealers, and ultrasonic sealers—will enable you to make informed decisions that align with your operational needs and goals.

Understanding Different Types of Sealing Machines: Pros and Cons for Various Industries

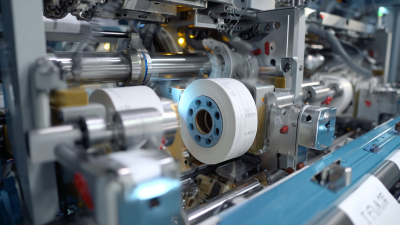

When selecting a sealing machine, it's essential to understand the various types available and their respective advantages and disadvantages. Different industries often require specific sealing solutions, from food packaging to construction applications. For instance, vacuum sealers are ideal for preserving food freshness and are widely used in the culinary industry, offering versatility in meal preparation. On the other hand, machinery such as robotic crack sealing machines is becoming increasingly popular in asphalt maintenance due to their efficiency and precision in sealing cracks.

Tips: Consider the scale of your operations when choosing a sealing machine. For small to medium businesses, a trailer-style sealing machine can be a more practical investment, providing the necessary functionality without the complexity of larger units. Additionally, assess the ease of operation and maintenance, as user-friendly designs can significantly reduce downtime and training costs for staff.

Another important factor is technological advancements in sealing machines. Modern machines often incorporate innovative features such as automation and augmented reality interfaces that can enhance your operational efficiency. Evaluate your industry requirements carefully, and choose a machine that aligns with your long-term business goals and needs.

How to Choose the Right Sealing Machine for Your Business Needs

This chart depicts a comparison of various sealing machines based on a subjective pros and cons index ranging from 1 to 10. Different industries can evaluate which type of sealing machine may be the most beneficial based on their specific needs.

Key Factors to Consider When Selecting a Sealing Machine for Your Production Needs

When selecting a sealing machine for your production needs, several key factors should be considered to ensure optimal performance and efficiency. Firstly, assess the type of packaging materials you will be using. Different sealing machines are designed to work with specific materials, such as plastic films, foil, or paper. Understanding the properties of your materials will help you choose a machine that can achieve the desired seal integrity and durability.

Additionally, consider the production volume and speed required for your operations. If you are working with high-demand products, a high-speed sealing machine will be necessary to meet your throughput goals. Evaluate the machine's cycle time and productivity rates to ensure it aligns with your production schedule. Finally, think about the machine's versatility and ease of use. A sealing machine that offers adjustable settings and is simple to operate can significantly streamline your workflow and minimize training time for staff.

Evaluating Production Volume: Choosing Between Manual, Semi-Automatic, and Automatic Sealers

When evaluating production volume for sealing machines, businesses must choose among manual, semi-automatic, and automatic options. For enterprises handling large-scale operations, automatic sealing machines are becoming increasingly vital. Recent market projections indicate that the automatic sealing robot market is expected to grow from USD 2.1 billion in 2024 to USD 5.6 billion by 2033, reflecting a compound annual growth rate (CAGR) that underscores the rising demand for efficient packaging solutions.

In contrast, smaller operations may find manual or semi-automatic sealers more fitting. These options require less upfront capital and are adaptable for lower production volumes, making them suitable for start-ups or niche markets. Notably, newer innovations in the vacuum sealing machine market anticipate growth to USD 1,878.5 million by 2035 at a CAGR of 4.8%, highlighting the importance of flexibility in business needs and the specific requirements tied to product types, such as food packaging. This analysis not only aids in understanding the current landscape but also guides businesses in making informed decisions about the right sealing machine tailored to their operational capacities and growth predictions.

How to Choose the Right Sealing Machine for Your Business Needs

| Sealer Type | Production Volume | Cost Range | Operator Requirement | Ideal Use Case |

|---|---|---|---|---|

| Manual Sealer | Up to 100 units/day | $100 - $500 | 1 Operator | Small businesses, limited budget |

| Semi-Automatic Sealer | 100 - 1000 units/day | $500 - $2000 | 1-2 Operators | Medium-sized production runs |

| Automatic Sealer | 1000+ units/day | $2000 - $10,000+ | Requires skilled labor | High-volume production, large manufacturers |

Material Compatibility: How to Ensure Your Sealing Machine Suits Your Product Packaging

When selecting a sealing machine for your business, material compatibility is a crucial factor that can significantly influence your packaging efficiency and product integrity. Different materials—whether plastic, foil, or paper—require specific sealing technologies to achieve optimal results. According to a recent report by MarketsandMarkets, the global packaging sealing machine market is projected to reach $4.5 billion by 2025, underscoring the importance of investing in a machine that aligns with your packaging materials.

To ensure the sealing machine suits your product packaging, consider the types of materials commonly used in your industry. For instance, thermoplastic materials typically require heat sealing, whereas flexible packaging might benefit more from ultrasonic sealing technology. A study from Smithers Pira indicates that flexible packaging is growing at a CAGR of 4.5% through 2024, highlighting the need for sealing solutions that can effectively accommodate these materials. Additionally, conducting compatibility tests with your specific packaging materials can prevent issues such as leaks or compromised shelf life, which could lead to significant product losses and customer dissatisfaction.

Cost vs. Performance: Analyzing Budget Considerations for Sealing Machine Investment

When selecting a sealing machine for your business, it is crucial to weigh cost against performance to ensure you are making a sound investment. Initially, budget considerations often lead businesses to opt for cheaper models; however, the long-term implications of such decisions can outweigh the initial savings. Inexpensive machines may lack the durability and efficiency needed for high-volume production, potentially incurring higher maintenance costs and downtime.

On the other hand, higher-end sealing machines, while requiring a larger upfront investment, typically offer advanced features and greater reliability. Assessing the specific needs of your operations is vital. Consider how the machine’s performance—such as sealing speed, consistency, and compatibility with various packaging materials—aligns with your production goals.

Balancing these factors can help you determine the most cost-effective solution that not only meets immediate budgets but also supports future scalability and reduces long-term operational costs.

Related Posts

-

2025’s Cutting-Edge Innovations in Wrapping Machines: A Global Buyer’s Essential Checklist

-

Quality Chinese Manufacturing and the Rise of the Best Sealing Machine in the Global Market

-

Comprehensive Guide to Choosing the Best Sachet Filling Machine for Diverse Product Applications

-

5 Top Innovations in Food Packaging Machines Revolutionizing the Industry

-

7 Ways to Choose the Best Coffee Packaging Machine for Your Business

-

Challenges Faced by Businesses Using Industrial Packaging Machines