Exploring Liquid Filling Machine Innovations at the 138th Canton Fair 2025

As the 138th Canton Fair approaches in 2025, the spotlight is set to shine on the latest innovations in various industries, particularly in the realm of packaging technology. Among the standout exhibits, the liquid filling machine is poised to demonstrate significant advancements that promise to reshape production efficiency and product quality. This year’s fair will highlight cutting-edge technologies designed to enhance the functionality and versatility of liquid filling machines, responding to the increasing demand for automation and precision in manufacturing processes. Companies are eager to showcase their breakthroughs, which not only cater to diverse liquid products but also provide sustainable solutions aligned with global environmental goals. Attendees can expect to engage with industry leaders and explore how these innovations contribute to optimizing workflows and reducing operational costs. The 138th Canton Fair thus represents a pivotal opportunity for businesses to connect and collaborate, driving forward the evolution of liquid filling technology.

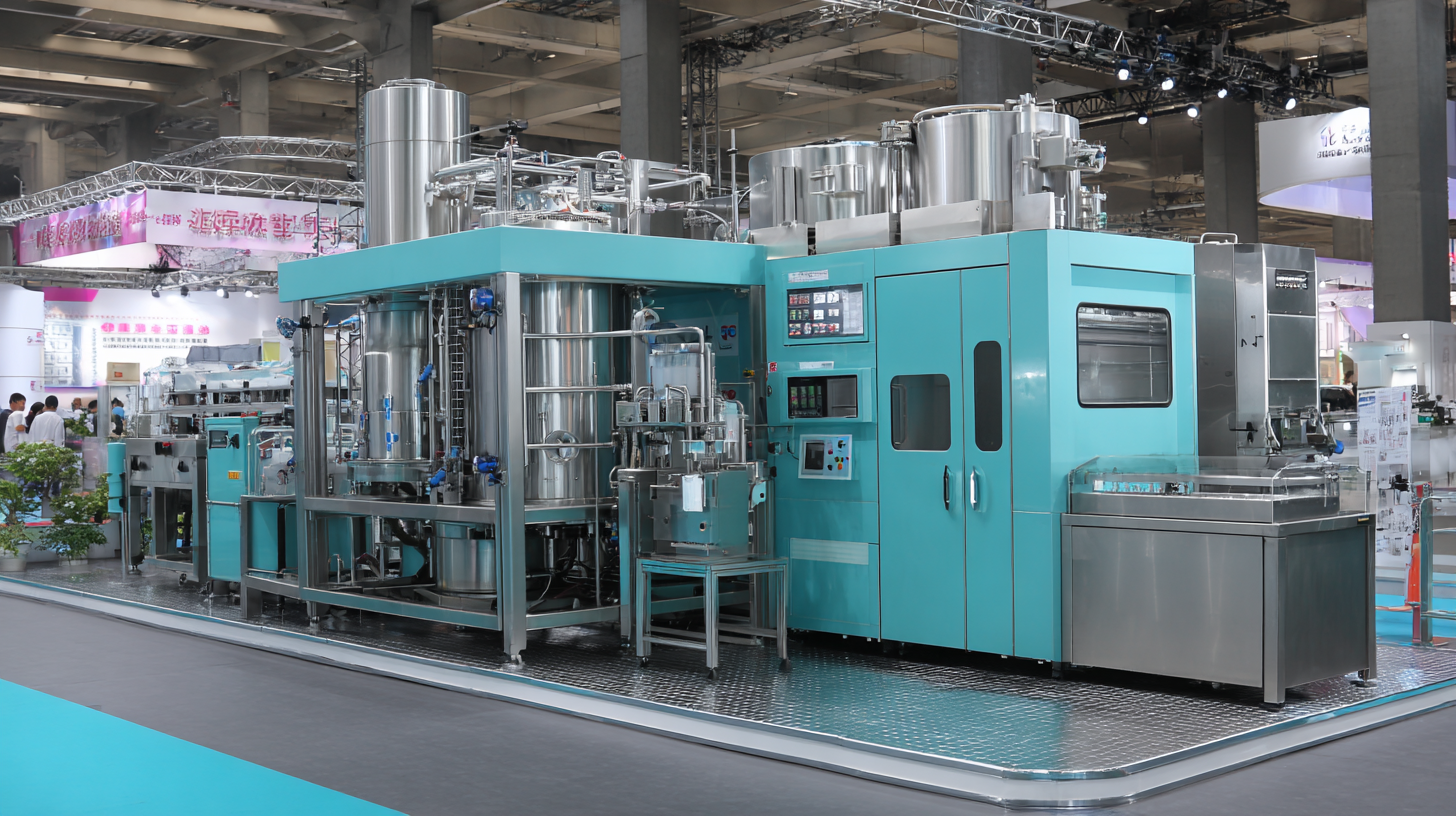

Innovative Technologies in Liquid Filling Machines Showcased at the Canton Fair

The 138th Canton Fair in 2025 serves as a pivotal platform for showcasing groundbreaking innovations in liquid filling machines. A wide array of manufacturers and technology firms have gathered to present their latest advancements, emphasizing efficiency, accuracy, and versatility. Attendees are particularly fascinated by smart filling systems that integrate artificial intelligence to enhance performance and predict maintenance needs, thereby minimizing downtime and operational costs.

In addition to smart technology, the fair highlights eco-friendly solutions aimed at reducing waste and energy consumption. Many exhibitors are introducing machines designed with sustainable practices in mind, featuring recyclable materials and innovative energy-saving mechanisms. The blend of advanced technology and sustainability reflects the industry's commitment to meeting the growing demand for environmentally conscious manufacturing practices, appealing to a broader spectrum of consumers and businesses alike.

Trends Shaping the Future of Liquid Filling Industry in 2025

As the 138th Canton Fair approaches in 2025, the liquid filling industry is experiencing transformative trends that signal a shift in operational efficiency and sustainability. According to a recent report by MarketsandMarkets, the global liquid filling machine market is projected to reach USD 6.5 billion by 2025, growing at a CAGR of 7.1%. This growth is largely driven by innovations in technology, such as automation and smart filling systems, enabling manufacturers to enhance productivity while minimizing waste.

One key trend shaping the future of the liquid filling industry is the integration of IoT (Internet of Things) technologies. These advancements allow for real-time monitoring and analytics, significantly improving process control and reducing downtime. Additionally, the emphasis on eco-friendly practices is prompting the adoption of sustainable materials and energy-efficient machines, aligning with global efforts to reduce carbon footprints. A study by Allied Market Research highlights that over 50% of manufacturers are prioritizing sustainability to meet consumer demand in 2025.

Tips for businesses looking to capitalize on these trends include investing in automated solutions for improved accuracy and efficiency and embracing sustainable practices to attract eco-conscious consumers. Staying abreast of technological advancements will not only streamline operations but also keep companies competitive in a rapidly evolving market.

Exploring Liquid Filling Machine Innovations at the 138th Canton Fair 2025

| Innovation Type | Description | Expected Impact | Adoption Rate (%) |

|---|---|---|---|

| Smart Sensors | Integration of smart sensors for real-time monitoring | Increased efficiency and reduced waste | 65% |

| Automated Processes | Fully automated filling and capping lines | Higher throughput with minimal labor costs | 72% |

| Eco-friendly Materials | Use of biodegradable and recyclable materials | Reduced environmental impact | 58% |

| Flexible Filling Technology | Adaptability to various container sizes and shapes | Supports product range diversification | 70% |

| Remote Monitoring Systems | Systems enabling remote operation and diagnostics | Enhanced uptime and troubleshooting capabilities | 60% |

Sustainability Initiatives in Liquid Filling Machine Manufacturing

At the upcoming 138th Canton Fair in 2025, liquid filling machine manufacturers are poised to showcase significant innovations centered around sustainability. As environmental concerns become increasingly urgent, many companies are adopting eco-friendly practices in their production processes. This includes the use of recyclable materials and energy-efficient technologies, which not only reduce the carbon footprint but also enhance the operational efficiency of the machines.

Moreover, the integration of smart technology in liquid filling machines is enabling more precise control of filling processes, ultimately minimizing waste. This innovation allows manufacturers to optimize the amount of liquid filled per container, resulting in fewer resources consumed and lower operational costs. The focus on sustainability at the Canton Fair highlights a crucial industry trend: a collective commitment to enhancing environmental responsibility while meeting the growing demand for efficient, high-capacity liquid filling solutions. As these initiatives gain momentum, they promise to reshape the landscape of liquid filling machine manufacturing for years to come.

Innovations in Liquid Filling Machines: Sustainability Initiatives

This bar chart illustrates the percentage of various sustainability initiatives being implemented in liquid filling machine manufacturing as observed at the 138th Canton Fair 2025.

Comparative Analysis of Liquid Filling Solutions from Global Exhibitors

At the 138th Canton Fair in 2025, the spotlight will be on the innovative liquid filling solutions showcased by global exhibitors. This event represents a critical platform for industries involved in beverage and pharmaceutical sectors to explore the latest advancements in liquid filling technology. As industry demands evolve, particularly with the growing emphasis on efficiency and precision, a comparative analysis of various filling solutions highlights the diverse approaches taken by different manufacturers around the world.

Among the notable trends seen in this comparative analysis is the increasing outsourcing of fill-finish services for biologics and vaccines to specialized contract manufacturing organizations (CMOs). This shift emphasizes the need for compliance, quality control, and specialized expertise, which are crucial for meeting the stringent regulations governing these sectors. By examining the liquid filling solutions presented at the fair, attendees can gain insights into how these innovations are driving improvements in productivity while addressing the specific needs of various markets, including beverages and pharmaceuticals.

Networking Opportunities for Industry Professionals at the 138th Canton Fair

The 138th Canton Fair in 2025 presents a remarkable platform for industry professionals to network and foster valuable connections. With its rich history and diverse attendance, this event attracts a global audience, providing excellent opportunities for attendees to engage with peers, suppliers, and potential clients in the liquid filling machine sector. The fair encourages collaboration among innovators and manufacturers, allowing them to share insights on the latest advancements and trends in the industry.

As participants explore innovative liquid filling machines, they will also have the chance to attend workshops and panel discussions that focus on best practices and emerging technologies. By interacting with industry leaders and innovators, professionals can gain substantial knowledge that will enhance their competitive edge. The networking sessions scheduled throughout the event will facilitate meaningful conversations, enabling attendees to forge partnerships that could lead to future projects and growth in their respective markets. The 138th Canton Fair is poised to be a pivotal event for those looking to expand their horizons in the liquid filling machine industry.

Related Posts

-

Exploring Top Alternatives to the Best Filling Machine for Efficient Production

-

Ultimate Guide to Choosing the Best Filling Machine for Your Business

-

5 Reasons Why the Best Liquid Pouch Filling Machine Revolutionizes Packaging Efficiency

-

The Comprehensive Handbook to Choosing the Best Filling Machine for Your Business Needs

-

Ultimate Guide to Choosing the Best Filling Machine for Your Business Needs

-

From China's Leading Factories: The Best Liquid Filling Machines Trusted by Global Buyers