Why Every Manufacturer Should Consider Investing in a Stick Pack Machine?

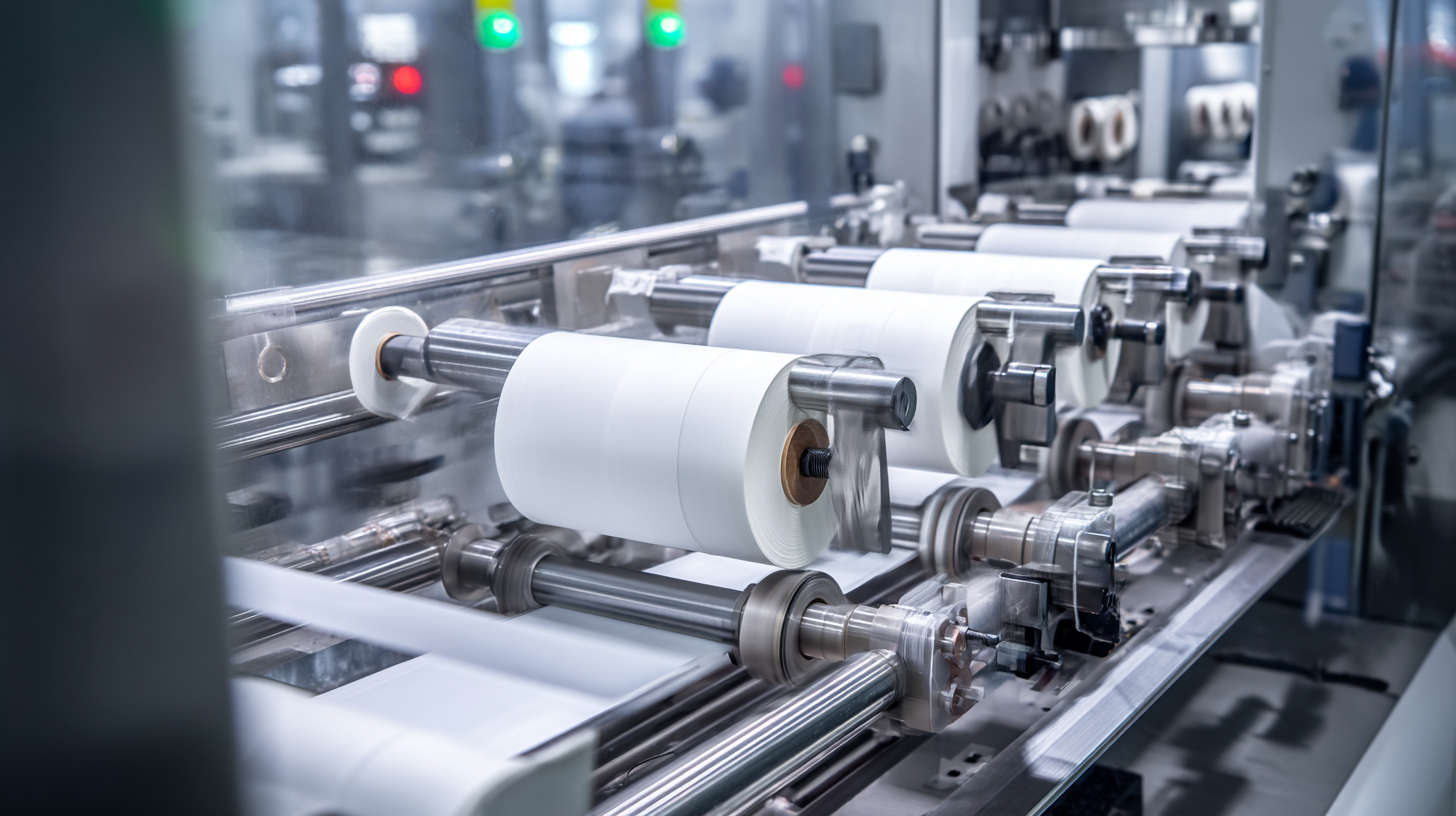

In the ever-evolving landscape of manufacturing, efficiency and innovation are paramount to staying competitive. One standout solution that is increasingly gaining traction among manufacturers is the stick pack machine. This advanced packaging technology offers a multitude of benefits, including enhanced product preservation, reduced packaging material waste, and improved shelf appeal. As consumer preferences shift towards convenience and portability, the stick pack machine emerges as a game-changer, enabling companies to meet the growing demand for single-serve products across various industries. By investing in a stick pack machine, manufacturers not only streamline their production processes but also enhance their overall brand value. This article delves into the compelling reasons why every manufacturer should seriously consider incorporating a stick pack machine into their operations.

Incorporating this innovative machinery can not only optimize production but significantly contribute to a brand's market presence in a competitive landscape.

Benefits of Stick Pack Machines for Streamlined Production Processes

Stick pack machines are revolutionizing the way manufacturers streamline their production processes. According to a recent report by Smithers Pira, the global stick pack packaging market is expected to reach $7.84 billion by 2025, driven by the rising consumer demand for single-serve products. This trend underscores the growing importance of stick pack machines, which enable efficient packaging of powders, solids, and liquids in convenient, easy-to-use formats. By automating the packaging process, manufacturers can significantly reduce labor costs and product waste, while increasing packaging speed by up to 200% compared to traditional methods.

Furthermore, stick pack machines contribute to enhanced product shelf life and improved brand visibility. In a study by Packaging Strategies, 70% of consumers reported that they preferred products with innovative packaging designs, which stick packs often offer due to their sleek, modern appearance. Additionally, stick packs provide superior barrier properties, preserving the quality of products and extending their usability. As manufacturers seek to remain competitive in a fast-paced market, investing in stick pack machinery not only optimizes production efficiency but also aligns with evolving consumer preferences for convenience and sustainability.

Key Features to Look for in a Stick Pack Machine Investment

Investing in a stick pack machine offers manufacturers a strategic advantage in the competitive packaging landscape. Key features to look for in such investments include automation capabilities, versatility in packaging sizes and materials, and quick changeover times. For instance, automated solutions can significantly enhance production efficiency, allowing manufacturers to meet increasing consumer demand for convenience while minimizing labor costs.

Moreover, advanced features like user-friendly interfaces and integration with existing production lines are crucial. Industry reports indicate that the demand for flexible packaging solutions is on the rise, with a projected growth rate of over 4% annually. With innovations continuously being showcased at events like PACK EXPO, manufacturers can explore cutting-edge technologies that promise rapid return on investment and streamlined processing. Thus, selecting the right stick pack machine can lead to optimized operations and a stronger market position.

Why Every Manufacturer Should Consider Investing in a Stick Pack Machine? - Key Features to Look for in a Stick Pack Machine Investment

| Feature | Description | Importance |

|---|---|---|

| Automation Level | Degree of automation from loading to packaging. | Increases efficiency and reduces labor costs. |

| Speed | Output speed in packs per minute. | Higher speed meets high demand, enhances productivity. |

| Versatility | Ability to package various products and sizes. | Adaptable to different market needs. |

| Ease of Use | User-friendly interface and controls. | Simplifies training and operating procedures. |

| Maintenance | Ease and frequency of maintenance required. | Reduced downtime and increased machine lifespan. |

| Size and Footprint | Dimensions and space required for the machine. | Fits within facility space constraints. |

| Quality Control Features | Integrated systems for checking pack integrity. | Ensures high product quality and minimizes waste. |

How Stick Pack Machines Enhance Product Shelf Life and Quality

Stick pack machines are revolutionizing the way manufacturers package their products, particularly in enhancing product shelf life and quality. These machines create innovative packaging that not only preserves the contents but also provides an airtight seal. This is especially beneficial for perishable goods, as it significantly reduces the risk of contamination and spoilage. By ensuring that products are sealed in a manner that prevents exposure to moisture and air, manufacturers can extend the viability of their offerings, making them more appealing to consumers who prioritize freshness.

Moreover, stick pack machines allow for precise dosing and portion control, which is especially important for items such as powdered drinks or pharmaceuticals. This precision not only enhances the overall quality of the product but also improves consumer satisfaction through consistency. Additionally, the compact and lightweight nature of stick packs increases the efficiency of storage and transportation, aligning with sustainability efforts within the manufacturing sector. As consumers become more conscious about product quality and packaging, investing in stick pack machines emerges as a strategic choice for manufacturers aiming to stay competitive in a rapidly evolving market.

Cost-Benefit Analysis: Stick Pack Machines vs. Traditional Packaging

Investing in a stick pack machine can significantly alter the landscape of packaging efficiency for manufacturers. Traditional packaging methods typically involve high labor costs and extensive material wastage. According to a report by the Packaging Machinery Manufacturers Institute (PMMI), companies utilizing stick pack machines can reduce packaging material waste by up to 30%, translating to substantial cost savings. Additionally, stick packs allow for precise portion control, minimizing product spillage and further enhancing profitability. The initial investment in a stick pack machine can range from $50,000 to $300,000, but the long-term benefits often outweigh these costs through increased productivity and reduced operational expenses.

Tip: When considering a stick pack machine, evaluate your production volumes. Higher output levels can lead to an expedited return on investment, making the transition more financially viable.

Moreover, stick packs are recognized for enhancing consumer convenience and brand differentiation. According to a survey by Euromonitor International, 65% of consumers favor single-serve packaging due to its portability and ease of use. Transitioning to stick pack technology not only aligns with consumer preferences but also positions your brand as innovative and forward-thinking in today’s competitive market.

Tip: Always factor in the adaptability of a stick pack machine to various product types. Machines that can handle diverse filling options provide greater flexibility and can accommodate market changes swiftly.

Steps to Successfully Integrate a Stick Pack Machine into Your Manufacturing Line

Integrating a stick pack machine into your manufacturing line can significantly enhance efficiency and product appeal. The first step is to assess your production needs and identify the right type of machine that aligns with your product specifications. According to a report by Freedonia Group, the stick pack packaging market is expected to grow by 5.4% annually, indicating a robust trend towards flexible packaging solutions. This growth highlights the importance of adopting modern machinery that meets consumer demand for convenience, especially in sectors like food, beverages, and pharmaceuticals.

Once a suitable machine is selected, it is crucial to plan for the installation and integration. This involves training staff on the new system and updating an existing production line to accommodate the stick pack machine. Industry data reveals that manufacturers who adopt automated packaging solutions can improve their output by up to 30%. Additionally, by customizing the stick pack size and design, you can further enhance product differentiation and meet specific market needs. Engaging with experienced suppliers during this phase ensures streamlined integration and minimizes operational downtime, setting the stage for long-term success in the evolving packaging landscape.

Why Every Manufacturer Should Consider Investing in a Stick Pack Machine?

This chart illustrates various factors like initial costs, maintenance costs, production speed, flexibility, and waste reduction that manufacturers should consider when investing in a stick pack machine. Understanding these metrics is crucial for making an informed decision about integration into manufacturing lines.

Related Posts

-

How to Optimize Your Production Line with Stick Pack Filling Machines

-

Ultimate Guide to Choosing the Best Filling Machine for Your Business

-

How to Choose the Right Filling Machine for Your Packaging Needs

-

Comprehensive Guide to Choosing the Best Sachet Filling Machine for Diverse Product Applications

-

How to Choose the Best Pouch Filling Machine for Your Packaging Needs

-

Unlocking Efficiency and Profitability through Best Pouch Filling Machine Innovations